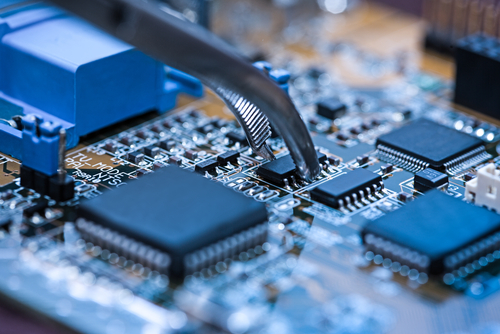

PCB Layout Services

While every job is unique, CA Design employs a battle-proven process for ensuring that your design meets all of the varied specifications you require. CA Design will not design your printed circuit board (PCB) in a vacuum. We work closely with the engineer, the fabrication house, and the assembly house to ensure a premium design.

While every job is unique, CA Design employs a battle-proven process for ensuring that your design meets all of the varied specifications you require. CA Design will not design your printed circuit board (PCB) in a vacuum. We work closely with the engineer, the fabrication house, and the assembly house to ensure a premium design.

CA Design is a configuration of expert and highly skilled printed circuit board (PCB) designers working together as a team to provide you with superior printed circuit board (PCB) design layout experts to meet your demanding schedules and technical requirements.

Our top PCB designers are all experienced and talented in PCB layout services. All our designers have at least 5 years experience, most have 25 years.

CA Design completes over 200 printed circuit board (PCB) designs each year and has repeat customers from as long ago as 1988. We do everything from Analog to Digital, High Speed Designs to Power Supplies. Our printed circuit design (PCD) Experts do very large logic boards, and very small interface printed circuit boards.

CA Design has established a business portfolio of 90% repeat customers, we can provide you with many references to prove the quality and timeliness of our PCB layout services.

No matter what printed circuit board (PCB) Design program you require or what printed circuit board (PCB) Design services you need including: printed circuit board (PCB) LIBRARY, Development and Maintenance….CA Design has printed circuit board (PCB) design layout experts and printed circuit board (PCB) design services for you!

There are many details of the design which must be addressed as soon as possible. To assist in the discussion of your board, CA Design has developed the “Intake Document” and the “Sign-off Sheet”. Please take a moment and download these Microsoft Word or Adobe Acrobat documents for reference.

The Intake Document is a very important document. Even if your board is small, by taking a minute to look at each question, we can ensure that nothing gets overlooked. Sometimes it is helpful to have the mechanical engineer review the Intake Document for mechanical concerns as well.

By getting as much information as possible up front, CA Design can better respond to your schedule requirements, and we ensure that we don’t paint ourselves into a corner later, when a conflicting requirement becomes obvious. For example, it’s easier to design for test from the start, than to add test points after the design is complete.

The Sign-Off Sheet is important as a measurement of schedule. It also ensures that the Engineer has a chance to review each step of the design before being committed to the design.

Testimonials

Our company has an onsite PCB Services Group. There are times when they have been backed up, or have planned closures and/or holidays. I have requested Todd Vela’s services because of Todd’s professionalism. When he commits to a task, he completes the task! Though Todd works remote, I never encountered remote service issues; it was as though he was onsite. He asks the right questions so the design is never compromised. The designs we worked on together flowed very well into the FAB house and back in house to our PCB Group. When forced to use external services, I have demanded and will continue to demand Todd…

Jay Lofthouse

I highly recommend Todd Vela as a PCB layout designer. I have found him to be fast, careful, open, willing, and professional. He has designed numerous boards for me all of which are now in Production. I don’t believe I have ever found him to make an error despite the sometimes incomplete information I’ve provided to him and the speed he’s able to work at. He is always careful to ask rather than make assumptions, but I’ve been very impressed with his ability to predict what I’m going to want and need. Todd is a bright, hard-working, trust-worthy individual who really knows his work. It has always been a pleasure to work with him.

Jennifer Charrier

SDP Electrical Engineering Manager Coherent, Inc.They were very open to input and were willing to do the work in a format that my in house designers could easily maintain. The designer I usually worked with was Todd V. and I found him to be very good at the mind-reading/error and issue finding sorts of activities that indicate either long experience or good engineering background or both. I doubt the designs I had them doing stretched their engineering capabilities though and almost none had any serious signal integrity issues to worry about. They were very careful and thorough. I had them recreate a number of old designs for which I had nothing but gerber files and old pdf copies of schematics (often not matching) and I didn’t find any errors at all. They found plenty of errors for me though. I worked with 3 or 4 different designers there over the years and all have been very professional and very open to input. They were also very quick. All the designs they made for me are now in Production.