New design-for-manufacturing (DFM) technology from Cadence Design Systems, Inc. has been made to perform real-time, in-design DFM checks. This new tech has been integrated into Allegro PCB Editor, which enables designers to identify and correct errors in an instant. This should happen even before sign-off, thus the need for quality Allegro PCB editor training which we’ll get into.

The benefits of finding possible errors include the reduction of rework by the design teams, shortening of design cycles, and acceleration of new product development and introduction processes. Thus, it potentially saves at least a day in each iteration and days to weeks overall.

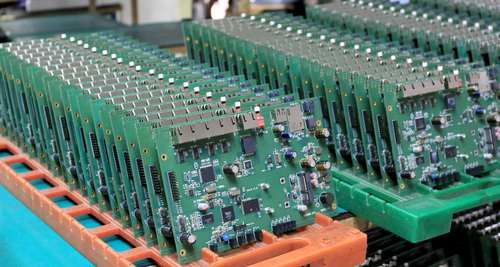

PCB Design

Using the DesignTrue DFM technology from Cadence Design, it can provide continuous in-design feedback while creating the design. So, it would eliminate the time-consuming and frustrating iteration of design-verify-fix between DFM checking teams and PCB designers.

The moment the PCB designers come to the final sign-off, they can already determine if their design has met the manufacturing rules. This will result in a smoother sign-off and hand-off to its manufacturing partner, along with a shorter and more predictable product design cycle.

Cadence will help you maximize your investment with a wide range of offerings, and CA Design can provide you Allegro PCB editor training for your personnel. The DesignTrue DFM technology of Cadence has been consistent with the proven Allegro constraint-driven online checking and design flow solution presently utilized in electrical, spacing, and physical rules. Likewise, the technology offers an array of checks to guarantee the manufacturability of the designs.

PCB Layout

The spacing between the features of copper can be verified in real-time, net-based, and independent of electrical rules. At the same time, the new technology offered at Cadence makes it easy to configure, reuse, and apply contextually manufacturing rules. The DesignTrue DFM technology would also support the import and export of DFM rules as it addresses over 2,000 advanced checks.

Moreover, it would employ a new and more user-friendly DRC browser, which is able to address a single class of errors per instance. The constraints are also highly configurable, as they have the ability to enable and disable groups and entire categories or individual rules. Take note that rules can be applied in etch mode, stack-up mode, and non-etch mode, providing designers with the ability to isolate layers, cutouts, and geometries. The said browser also features integrated DRC description with corresponding graphics. It provides a DRC count chart and characterizes DRCs by type. Thus, users are able to sort quickly, browse and review, and waive DRCs or exactly the opposite.

PCB Editor Training

Basically, if you consider Allegro PCB editor training, you can rest assured that your PCB designers are working on the board correctly even for the first time. The increased complexity of the PCB should be able to extend the design cycles and making the prediction a bit more challenging. The constraints should take into account the manufacturing, physical, and electrical considerations. As a result, it would eliminate the unnecessary iterations with the sign-off processes in manufacturing, saving days to weeks of time.

Speeding up the development and introduction of new products is the main priority for the customers. Customers have relied on the online checking solution and the Allegro constraint-driven flow for the electrical and physical domains for over 15 years. Perhaps it is time that you rely on the services of Cadence Allegro, as well as take advantage of CA Design’s Allegro PCB editor training.

CA Design Offers Allegro and OrCAD PCB Services nationwide as well as to the Following Cities and Counties: Cadwell, Cotati, Fredericks, Kenwood, Liberty, Orchard, Penngrove, Petaluma, Roblar, Rohnert Park, Roseland, San Francisco, Sebastopol, and Silicon Valley